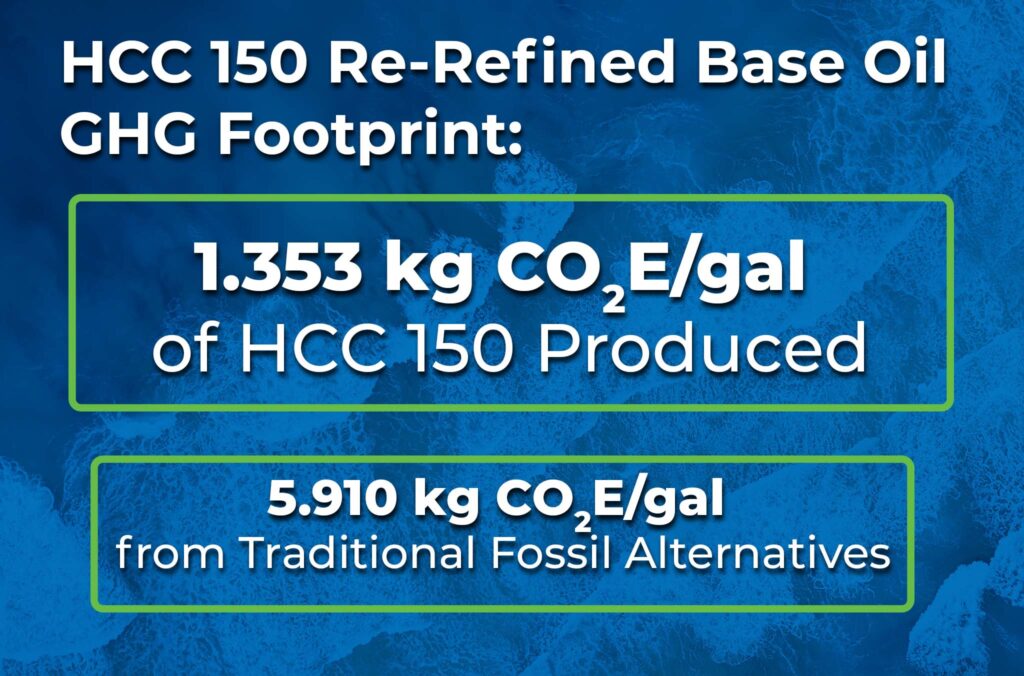

Crystal Clean Re-Refined Base Oil Produces 77% Less Greenhouse Gas Emissions Than Traditional Base Oil Products

Crystal Clean, Inc., a leading provider of specialized environmental and waste management solutions to commercial and industrial end-markets, is proud to share the results of an in-depth life cycle assessment (LCA) for its HCC 150 re-refined base oil. The study, conducted by environmental consulting firm ClimeCo and critically reviewed by an independent third party, reveals a 77% reduction in greenhouse gas emissions (GHG) compared to traditional virgin base oils.

The LCA followed stringent standards, including ISO 14067 and the API TR 1533 Sector Specific Guideline, ensuring transparency and accuracy. It analyzed the cradle-to-gate emissions of HCC 150 compared to traditional fossil alternatives, accounting for all stages from raw material acquisition to base oil production. The results reveal that HCC 150 has a GHG footprint of only 0.422 kg CO2e per kilogram of base oil, underscoring the product’s environmental benefits.

“Crystal Clean’s commitment to sustainability is at the heart of our vision to help the business world run cleaner,” said Brian Recatto, President & CEO of Crystal Clean. “The life cycle analysis of HCC 150 showcases our ability to provide solutions that not only meet the industry’s highest standards but also help our customers achieve their environmental goals. This product is proof that sustainability and performance can go hand in hand.”

The significant reduction in the GHG footprint of HCC 150 compared to traditional base oils is achieved through Crystal Clean’s oil re-refining process, which transforms used motor oils and lubricants into high-quality Group II base oils. The process avoids the environmental burden of crude oil extraction and refining, conserving resources while delivering products that meet the same API and ILSAC performance standards as their virgin counterparts. Crystal Clean’s used oil re-refinery is one of the largest re-refineries in North America, with the capacity to re-refine more than 75 million gallons of used oil annually.

The LCA confirms that by using re-refined base oils like HCC 150, businesses can significantly lower their carbon footprints without compromising quality or reliability. High-volume users of base oil may see a substantial impact when switching to a re-refined base oil. For example, a company using one million gallons of base oil annually could reduce its GHG footprint by over 5,000 short tons by switching to HCC 150.

“The environmental benefits of HCC 150 extend beyond emissions reductions,” commented CEO Recatto. “By creating a circular economy, re-refined base oils minimize waste, reduce the demand for virgin oil extraction, and conserve natural resources.”

Companies adopting HCC 150 can also make substantial progress toward achieving their Scope 3 emissions reduction goals. With increasing demand for low-carbon products, HCC 150 positions Crystal Clean as a leader in the environmental services sector and a champion of the circular economy.